Precision bar turning

Juradec, the precision bar turning specialist

Juradec is equipped with brand new latest-generation CNC machines tailored to manufacturing both simple and complex high-precision small parts. Our equipment enables us to handle any production from large volumes to small runs, and we also have CNC machines dedicated to prototyping. We tackle a host of challenges and constantly put our equipment to the toughest tests, all to ensure customer satisfaction.

Machine inventory

Equipped with 37 latest-generation CNC machines

Precision

Quality, high-precision CNC machines

Variety of parts

Able to manufacture components in many different fields of activity

OUR MACHINES

A VARIED MACHINE FLEET

Machines harnessed for your projects

CNC machines

Precision bar turning

Juradec, the precision bar turning specialist

Why choose us ?

We meet all your needs

Analysing the request

Feasibility

Production

Delivery

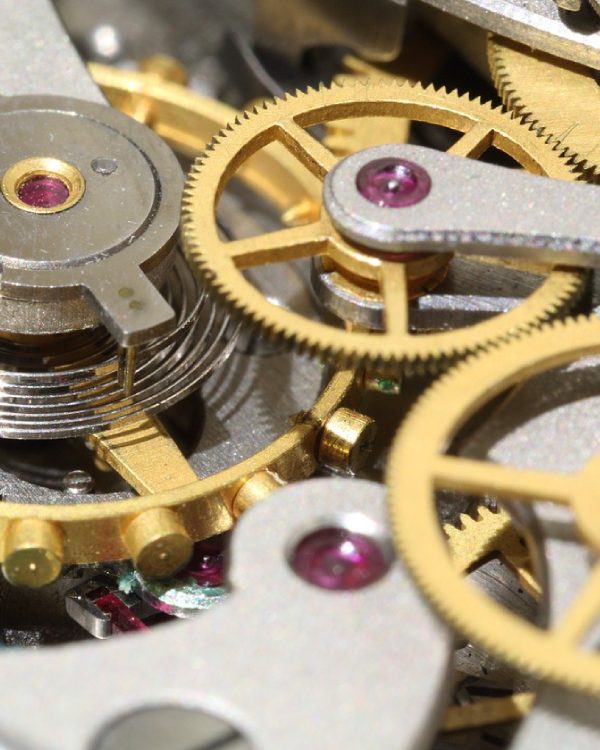

Watchmaking

High-end watchmaking quality control

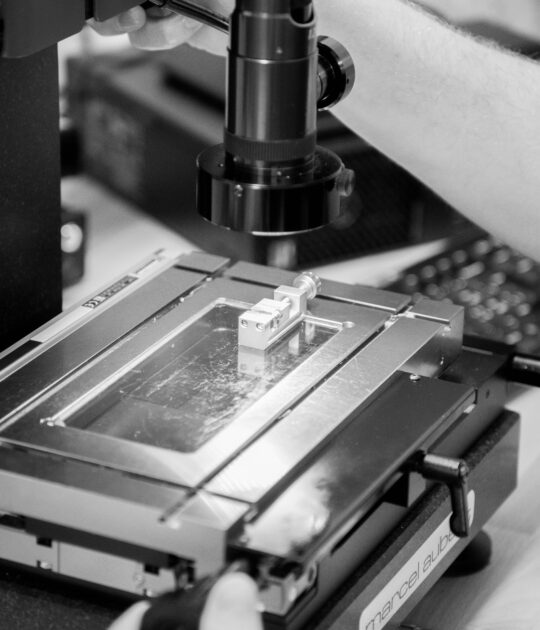

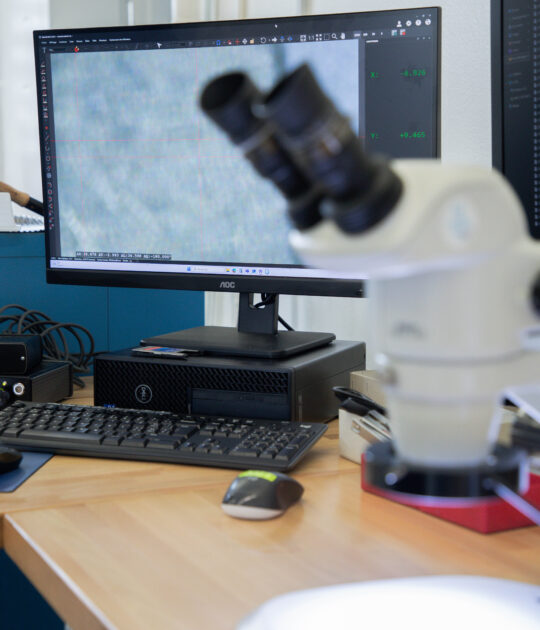

At Juradec quality control is an essential stage in our manufacturing process. Every watch component undergoes rigorous controls to ensure exceptional quality for our demanding customers.

Our quality experts perform precision tests and aesthetic checks at every stage of production, to ensure the highest standards of performance and reliability.

We invest in the latest technologies to support the quality control process. We have a Keyence checker, which automatically measures the parts, as well as Marcel Aubert devices. We also use the Quickcontrol software for all the inspection reports that we send to our customers.